TBZE-series robust pumps are best suited for draining in civil engineering, but can be also used for general pumping purposes.

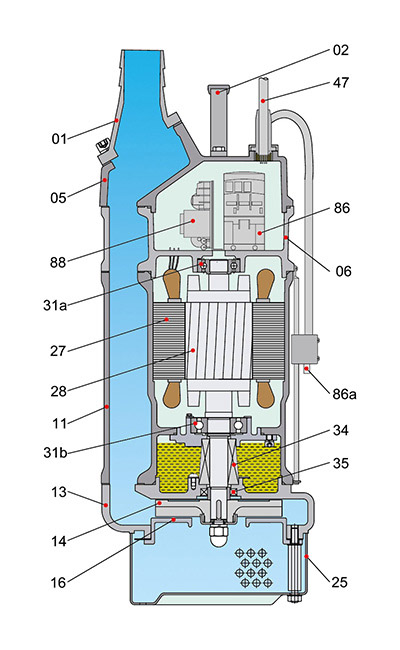

Motor and pump casing is made of rigid cast iron for long-lasting durability. Maximum submersion depth is greatly increased due to mechanical seal resistant to high pressure. Semi-open impeller made of high chrome alloy in combination with wear plate (ductile iron) achieves superior durability.

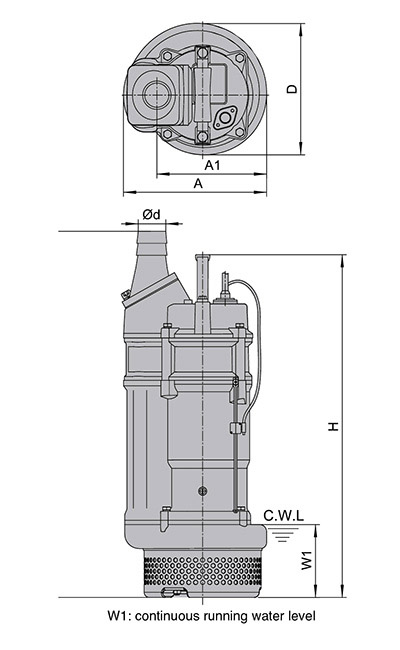

Effective motor cooling due to execution of discharge channel integrated into the motor housing. Space saving design due to a top outlet.

Discharge outlet from 50mm to 100mm, Motor from 1,5kW to 5,5kW.

TBZE series pumps operate automatically with the help of bulit-in intelligent control system. This system helps the end-user to achieve electricity cost reduction at the construction or industrial site.

Key features of TBZE intelligent control system:

- Protects against reverse phase, ensuring correct impeller rotation;

- Protects against open phase or impeller jam, thus prevents accidental damage;

- Automatically stops the pump in case of overload, abnormal voltage with the recovery after 5 minutes;

- The pump stops working at high temperature, and will automatically restart after cooling to the specified temperature;

- The water level sensor's height is adjustable to control pump operation;

- The pump stops working within 60seconds when water level is below the water level probe keeping downtime for 180 seconds, after the 180 seconds, meanwhile the water level is above the water level sensor, the pump works again;

- Rapid assessment of the pump’s operation and malfunction history.